0110 years of researches

SoliTek Research and Development department

SoliTek solar technology research company

UAB SoliTek R&D (head Julius Denafas) together with scientific institutions, universities and research centers from all over the world conducts research on solar technologies that help to develop more and more energy-efficient solar modules and is looking for new ways to use solar energy more efficiently. We work hard to increase the efficiency, durability and resistance to external factors of our solar modules.

Since 2013, SoliTek R&D, formerly UAB Baltic Solar Solutions, has been developing and producing polycrystalline solar cells at its Visoriai plant, the only solar cell plant in the region. In 2019, the Finnish company VALOE took over the production of cells and is developing the production technology of double-sided IBC-type solar cells and modules in the former SoliTek R&D premises in Vilnius.

SoliTek R&D focuses on the research of solar modules and other technologies, the better application of solar electricity and other activities since 2019.

Recycling project for solar cells and solar modules

In an international project under Horizon 2020, together with our partners, we produced the first solar cells only from recycled materials, using defective cells and their waste. New solar cells and modules were made from recycled materials, and their parameters and quality were measured. No significant deterioration in the quality of new cells using recycled materials was observed.

The CABRISS project, which was implemented under Horizon 2020, involved 16 partners - 11 companies and 5 research institutes from various European countries. The aim of the project was to purify the waste generated during the production of the modules - shards of silicon and solar cells, and to make new silicon wafers from them.

The development of the solar cell and module recycling technology was facilitated and carried out by the project partners Loser Chemie from Germany, CEA-INES, the French national solar energy institute, and SINTEF, an independent research organization in Norway. They estimate the cost of processing at between € 75 and € 100 per t.

More than 95% of the waste was recycled solar cell materials - glass, metals, semiconductors, polymers. Extracting materials is not easy, as solar modules are manufactured to last 30 years or more in difficult outdoor conditions. So dismantling the module and separating the tightly laminated layers was the biggest technological challenge.

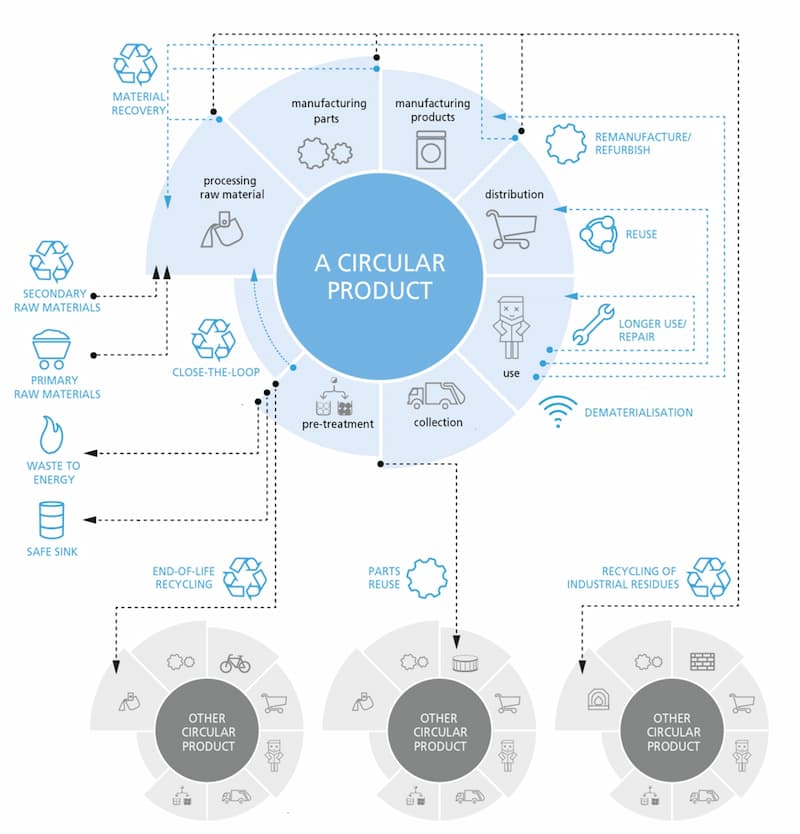

Together with its partners, SoliTek was one of the first in Europe to test the circular economy model in the solar manufacturing sector, and the methods developed and tested have led to a more environmentally friendly product with a lower footprint of greenhouse gases.

In collaboration with leading European solar technology research laboratories, we have also gained a wealth of knowledge about the impact of material quality on the final quality of solar cells and solar modules.

The efficient use of solar cell materials is critical to the successful growth of the solar technology sector. If we will be able to recycle solar modules, the more efficient, cheaper and more environmentally friendly solar energy will be.

Research of Bifacial Solar Modules

SoliTek R&D participated in project Eco-Solar, under Horizon 2020. Together with the partners in this project, the International Solar Research Center in Konstanz (ISC-Konstanz), prototype eco-friendly double-sided solar modules capable of absorbing light from both the top and bottom have been developed and manufactured. This type of solar module allows to generate up to 25% more electricity from the same area than conventional solar modules. Double-sided solar cells are laminated between two sheets of tempered glass, and a moisture- and chemical-resistant binder is used in the production. Our manufacturing recipe ensures that the elements last almost twice as long as standard solar modules. Due to the longevity and efficiency of the elements, the cost of production per kilowatt hour decreases, resulting in an increase in overall profitability

SoliTek RnD

Production of solar cells with process modifications to save chemicals and reduce production time;

The production process of Ecosolar cells has a 4% lower environmental impact (CO2 footprint) compared to standard;

In terms of price, the Ecosolar process reduces the cost of a solar cell by about 2%;

The first tests of bifacial technology were performed in this project. We produced the first SoliTek glass-to-glass solar modules using solar cells with bifacial technology.

Results:

SoliTek R&D, after the project, began to use less polluting production in production process, as certain process modifications have been introduced in diffusion and surface etching processes. Valoe Cells (the new owners of the cell line) is currently applying some of the Ecosolar project process modifications to its production.

A completely new prototype of the glass glass bifacial module on the market at the time was produced during the project in 2017, over time it became a usual solar panel from SoliTek

Circular business models for the solar industry - CIRCUSOL

Resource efficiency is a critical success factor for the sustainable development of the solar energy industry. The Product-Service-System (PSS) model based on performance-based third-party management is seen as an important part of the circular economy to promote resource efficiency while reducing waste. CIRCUSOL aims to set an example for the solar industry, demonstrating the path to a GHS business model to contribute to the transition of a circular economy in Europe. In collaboration between consumers and the entire value chain, CIRCUSOL will develop 2 blocks of the circular PSS model: circular product management through re-use / refurbish / remanufacture strategies complemented by recycling and added value in new product-as-a-service PV markets: residential, commercial and users of massive PV systems.

Project objectives:

Implementation of circular business models based on product-service-system (PSS) model in five demonstrations.

Marking of secondary modules and secondary batteries and development of certification protocols.

Business model development of solar module for circular technical design.

Validation of innovation methodologies and tools for the systemic circular economy model in business and academia.

Policy recommendations.

A new ICT platform for data generation, hosting, analysis and sharing throughout the value chain.

Project duration:

June 2018 to November 2022 (4.5 years)

SoliTek RnD contribution

Analysis of PV module ring problems and product technical design;

Contribute to the development of standards for the re-use of the PV module;

Development of a business model in the field of secondary PV modules.

Results:

Report on the shortcomings of the PV module's ring design and possible changes to increase the ring.

2 Scientific articles we Manufactured mini-modules with lead-free ribbons (contact strips connecting solar cells), fluoride-free backsheets, laminated NFC tags and RFID tags glued from the outside.

A ready-made business model for recycling solar modules.

Efficiency Study of Solar Modules - Super PV

The consortium of this project consists of 26 partners representing different industries and research institutes. The project coordinators are two Lithuanian companies - Solitek and Protech - which ensure smooth work during the project.

The aim of the project is to reduce the cost of harmonized energy or harmonized electricity (also known as LCOE) by 26% to 37%. And this cartel will be pursued in three different areas, such as solar module design and innovation, power electronics and integrated digital tools.

This project explores solar module innovations such as:

Coatings of nanoparticles are sprayed on the surface, which have anti-reflective and anti-soiling properties. This innovation should increase energy output by increasing the amount of light absorbed by solar modules and reducing surface dust.

The rear glass of the solar module with white paint in the gaps between the solar cells, by means of which more transmitted light, which would not normally be absorbed, is reflected back to the active surface of the solar module.

Instead of junction boxes, individual diodes are embedded in the laminate of the solar module itself, which reduces the amount of raw materials required for the production of solar modules and increases the light absorption of the rear side due to the smaller covered area.

Recycling tools are also being developed and developed in laboratories and methods are being tested to recycle various types of modules for recycling, such as CIGS flexible solar cells or conventional crystalline silicon modules that do not use any polymers for lamination and use gas instead.

The field of power electronics is evolving electronic devices such as micro-inverters that test other semiconductors, such as gallium nitride. Various optimizers or Smart boxes are also being tested, which have Rapid shut down functions that ensure safety against any fire or other harmful hazards to the solar power plant. These advanced electronics are also expected to increase the efficiency of the energy transmitted from the solar power plant.

In the field of digital tools, the partners are developing innovations such as a digital platform that will be able to model and simulate a solar power plant to create the most efficient version of the power plant and reduce and calculate the exact cost of installing a solar power plant. Also, a lot of attention is paid to the development and training of the digital twin, which will be able to predict the generation curve of the solar power plant using the information gathered from the project's solar power plants and all the sensors in the power plant.

The duration of the project: June 2018 to November 2022.

SoliTek R&D team develops and operates innovations and demonstration plants, coordinates and tests solar modules with innovations and collects information for project partners, who use this information to analyze results and develop digital tools.

During the project, the innovations of solar module technologies of recent years will be tested under equal conditions and the best of them will be easily transferred to the mass production of solar modules.

Innovative generation of green electricity and storage solutions for e-transport

The project is being implemented with the participation of the Agency for Science, Innovation and Technology (MITA) in 2014-2021. In the Norwegian Financial Mechanism Program "Business Development, Innovation and SMEs", which finances the implementation of green innovation ideas.

The market for renewable electricity and electric vehicles is constantly growing, which requires convenient and innovative solutions. The need increased and tightened by environmental standards and state-implemented green transformation measures. The SoliTek R&D project aims to make the daily life of electric vehicles easier - the solution being developed will allow them to be loaded autonomously and conveniently.

The innovative solutions being developed aim to contribute to the more efficient use and development of renewable electricity technologies. It is planned that the project will develop 4 prototypes (light photovoltaic module prototype, light photovoltaic folding PV power plant prototype, mobile electric vehicle charging station prototype, next generation autonomous bus station (pavilion) prototype) and tested in real conditions. Solutions will also be sought to recycle end-of-life products.

The project has been running since 2021. July 7 until 2024 April 30

Project goals and objectives:

To develop a good and high-quality product during the project implementation and to explore the possibilities of recycling them at the end of their service life.

Creation, implementation and development of innovative energy generation and storage system technologies.

Contribute to a more efficient use of renewable electricity in the public and private transport sectors by developing green energy and reducing GHG emissions.

SoliTek responsibilities:

Development of a layout and prototype of a mobile electric car charging station. The function of the device is to charge the electric vehicle in the shortest time from the electricity stored in the integrated battery tank;

Development of a model and prototype of a bus autonomous stop (pavilion);

Project coordination.

The market for renewable electricity and electric vehicles is constantly growing, and the need for new solutions is growing due to more strict environmental standards and public policy on clean energy.

#NorwayGrants #VersloPletraInovacijosMVI #Innovation

High-performance low-cost solar modules. HighLite

High-performance low-cost modules with excellent environmental profiles for a competitive EU PV manufacturing industry.

Objectives of the project:

- Demonstrate high-efficiency solar cells in in pilot-line manufacturing.

- Develop industrial tools for assembly of thin (100-160 μm after texturing) cut-cells.

- Develop modules tailored for various distributed generation applications (buildings, cars, etc.).

- Demonstrate improved cost and performance against state-of-the-art commercially available modules.

Timing: 2019-10-01 – 2022-09-30 (3 years)

Total budget: 15 087 603,61€

Solitek R&D budget: 108 500,00 €

The HighLite project aims to substantially improve the competitiveness of the EU PV manufacturing industry by developing knowledge-based manufacturing solutions for high-performance low-cost modules with excellent environmental profiles. The project will focus on bringing two competing technologies to high technology readiness levels (TRL 6-7) taking profit of the unique strength and expertise of cutting-edge European institutes and industries in the field of c-Si devices and passivating contacts.

The first one is based on shingle assembly (similar to rooftiles with edges overlapping) of 2-side contacted silicon heterojunction (SHJ) cut-cells. The second one is based on back-contact assembly of interdigitated back-contact (IBC) cut-cells with high temperature passivating contacts. In both approaches, cutting cells into smaller segments for assembly has multiple benefits (e.g. improved performance, increased modularity). In order to achieve those benefits, the HighLite project will develop and optimize innovative solutions at both cell and module levels. Both technologies will be tailored for various applications (building-applied PV, building-integrated PV, and vehicle-integrated PV). The PV modules developed in HighLite will demonstrate higher performance, lower LCOE, and improved environmental profiles compared to commercially available PV modules.

Solitek RnD part: Cost of ownership (CoO) calculations of HighLite products.